Biodegradable filler masterbatch

- FuTai

- LiaoNing, China

- Prompt delivery

- 500T per month

Highlights

1. Perfect dispersion and optimized flow properties ensuring easy processing.

2. The talc grades used in our filler master batches are of excellent quality allowing much higher loading compared to conventional filler master batches.

3. Non-toxic and harmless, and it is not polluted to the environment.

4. Cost-effective solution for manufacturer.

Definition of biodegradable filler masterbatch

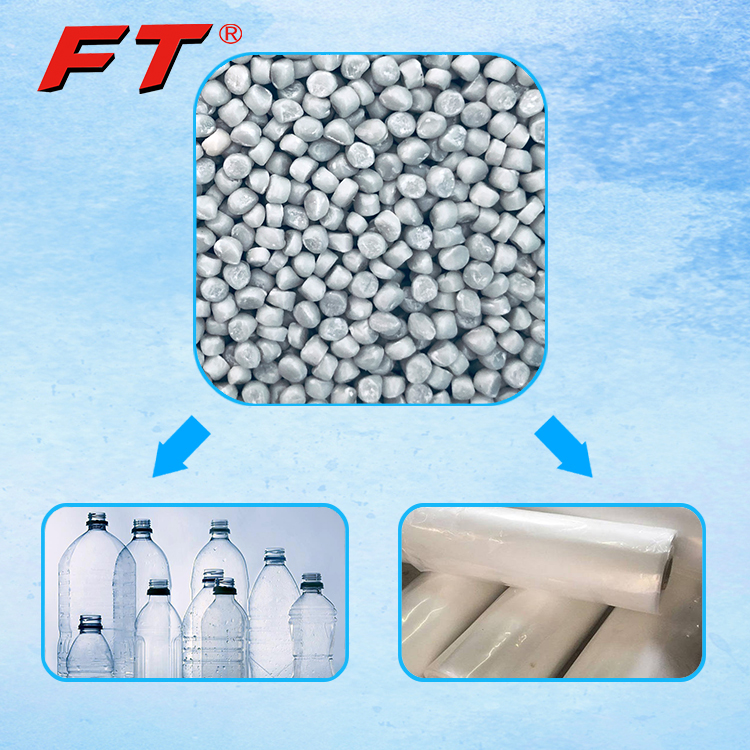

Biodegradable filler masterbatch is a material of talc/corn starch and bio-resin as the carrier. It has compatibility with: PLA, PBS, PBAT, TPS.

Introduction of Biodegradable filler masterbatch

The effect of plastics on the environment is now a worldwide concern. Disposal methods are very limited, while its usage is more increasing. Plastics are needed for our current society. Living without plastics is nearly impossible to believe. Increasing concern among people about this problem has inspired interest in the field of biodegradation of polymers.

Biodegradable masterbatches is one of the most recent products developed by our company which is thermoplastics and environment-friendly. Our Biodegradable Masterbatch products can be combined with a various material to modify chemical properties perfectly matched to the various applications. We are Biodegradable masterbatch manufacturer who provide the premier Industrial Grade Biodegradable Masterbatches within the market. Our biodegradable masterbatch products guarantee that waste can be decreased or recycled easily, reducing carbon footprints across the business.

Product features:

Futai biodegradable filler masterbatch has great features:

★ Perfect dispersion and optimized flow properties ensuring easy processing.

★ The talc grades used in our filler master batches are of excellent quality allowing much higher loading compared to conventional filler master batches.

★ Biodegradable in composting environment.

★ Cost-effective solution for manufacturer.

★ Non-toxic and harmless, and it is not polluted to the environment.

Application of biodegradable filler masterbatch:

Biodegradable/ Compostable Shopping bags / Carry bags

Blown film extrusion

Injection Molding

General parameters of Biodegradable filler masterbatch:

Product type | inorganic powder filler | starch filler |

Ingredients | PBAT, PLA, talc powder | PBAT, PLA, starch |

Appearance | White particles, smooth surface, uniform size and no color difference | granular, smooth surface, uniform size, no color difference |

SiO2 | 55-62% |

For more info about the products, please feel free to contact our technician representatives.

We can also supply according to customized quality demand.

Instructions:

1. Before using, the masterbatch shall be dried continuously for 2-4 hours at 80 ° C in the air blast or vacuum oven.

2. The disposing proportion of the degradable masterbatch can be 20% - 40%, and the amount can be adjusted according to actual needs.

3. The processing conditions can refer to the processing and conditions of the base plastic.

Company Profile

Founded in 2009, Dalian Futai Mineral New Material Technology Co., Ltd. is a comprehensive enterprise integrating mining and processing of mineral products, R & D and production of masterbatch, product sales and service, formerly known as Yingkou Jintong New Material. Since its establishment, the company has been committed to the processing of talcum powder and related products masterbatch, and has won unanimous praise in the industry. It is a professional technical production enterprise and has won a number of awards from relevant associations in the industry.

Company Resources

The company invests in the exploitation of a talc mine with explored reserve of 800,000 tons and a planned annual mining volume of 50000 tons. It integrates two processing plants, including 4 Airjet millers, 2 Raymond millers and 1 vertical roller grinder, with an annual production capacity of 50000 tons of powder.

In addition, the factory is equipped with 3 twin-screw granulation production lines, 1 non-carrier granulation production and drying line, which can customize and process various masterbatch products according to different needs of customers from domestic and overseas.