PP Talc Filler Masterbatch

- FuTai

- LiaoNing, China

- Prompt delivery

- 500T per month

Highlights

1. High quality talc with micronized particle size enhances the PP talc masterbatch properties.

2. Talc PP masterbatch is best free dust production, improve working environment.

3. PP talc filler masterbatch can improve processing efficiency.

4. Filler MB PP talc is good Cost-saving solution for the manufacturer.

Product features:

Talc, characterized with its lamellar structure, represents one of the most useful mineral fillers which are compatible with the polypropylene (PP). The talc can be easily and uniformly dispersed in the PP matrix.

Polypropylene (PP) is one of the most extensively produced polymers, especially widely used as automotive parts due to its good impact resistance as well as processability. The addition of fillers into PP matrix has been an accepted route to achieve enhancement in material properties or/and cost saving possibilities.

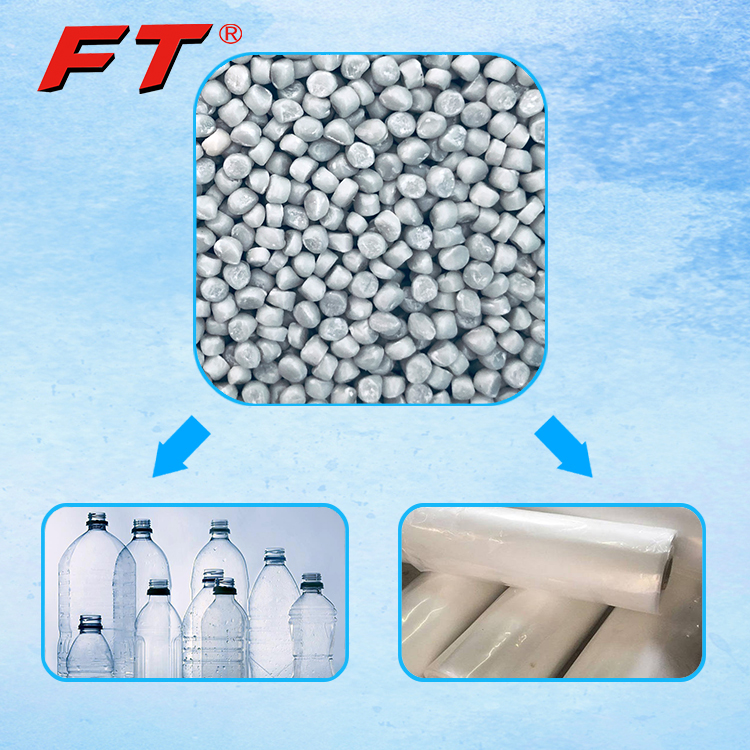

PP talc filler masterbatch is made by pelletizing from talc powder with PP as carrier. Compared with talcum powder, the talc PP masterbatch has better processing performance and many advantages in processing final product, such as no dust pollution, easy blanking, uniform mixing, improving the working environment, increase the processing efficiency, etc.

Product Application:

Widely used in modified PP, blowing films, injection molding, blow molding, extrusion, etc.

Automotive application

Electricals application

Film and bottle application

Sheets and pipe application

Regular Specification:

Model: FTP series, FTP80A, FTP12A, FTP20A, FTP30A.

Talc mesh: 800-3000 according to customer demand

Carrier percentage: 20%-30%

We can also process according to customized quality demand.

Company Profile

Founded in 2009, Dalian Futai Mineral New Material Technology Co., Ltd. is a comprehensive enterprise integrating mining and processing of mineral products, R & D and production of masterbatch, product sales and service, formerly known as Yingkou Jintong New Material. Since its establishment, the company has been committed to the processing of talcum powder and related products masterbatch, and has won unanimous praise in the industry. It is a professional technical production enterprise and has won a number of awards from relevant associations in the industry.

Company Resources

The company invests in the exploitation of a talc mine with explored reserve of 800,000 tons and a planned annual mining volume of 50000 tons. It integrates two processing plants, including 4 Airjet millers, 2 Raymond millers and 1 vertical roller grinder, with an annual production capacity of 50000 tons of powder.

In addition, the factory is equipped with 3 twin-screw granulation production lines, 1 non-carrier granulation production and drying line, which can customize and process various masterbatch products according to different needs of customers from domestic and overseas.