Magnesium Hydroxide For Engineering Plastic

- FuTai

- LiaoNing, China

- Prompt delivery

- 3000T per month

Highlights:

1. Excellent flame retardancy and smoke suppression properties

2. Non-halogenated

3. Cost effective replacement for Alumina Trihydrate (ATH), Lower hardness than ATH resulting in longer equipment life

4. Thermally stable to 340°C, suitable for engineering plastic

5. Non-corrosive as compared to halogen or phosphorous-containing compounds

Introduction of Magnesium Hydroxide for engineering plastics:

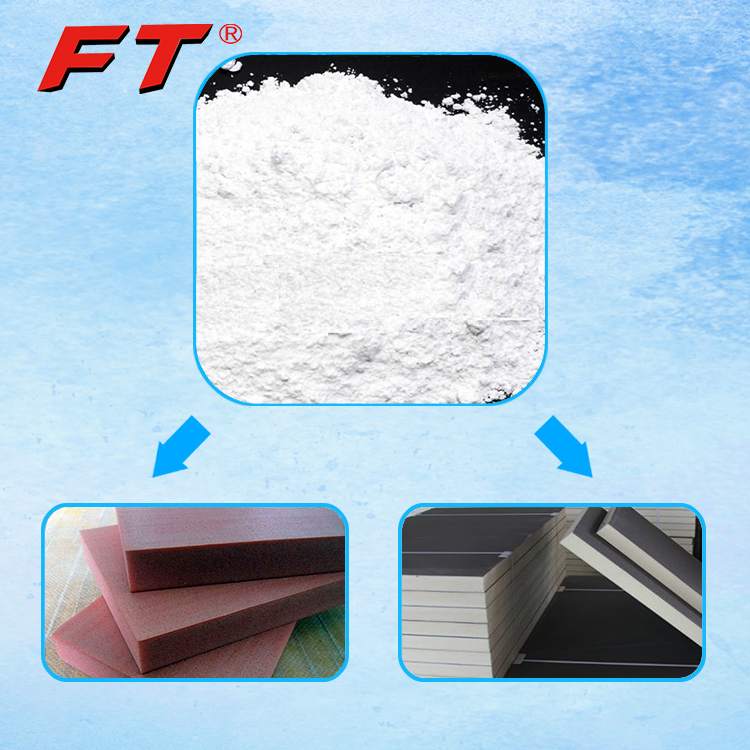

Magnesium Hydroxide for engineering plastics is a new low smoke and halogen-free environmental flame retardant with three functions of flame retardant, smoke retardant and filling.

Because of its good buffer performance, higher activity and adsorption capacity, deal with the use of safe and non-corrosive, non-toxic, harmless, and many other unique properties, it is called "green safety neutralizer", "environmental friendly fire retardant" and "the third base". Therefore, it is one of products that are beneficial to implement sustainable development strategy, environmental protection and ecological development.

Flame retardants are chemical additives used in plastics, coatings, and other products to inhibit flame sustenance. Magnesium hydroxide is used with a resin or similar base material as flame retardant filler. This magnesia compound is physically mixed with the base material (and “additive flame retardant”).

Applications of Magnesium Hydroxide for engineering plastics:

★ Flame retardant nylon

★ Low smoke and halogen free flame-retardant wire and cable

★ Building materials such as Flame-retardant coating and plastics,

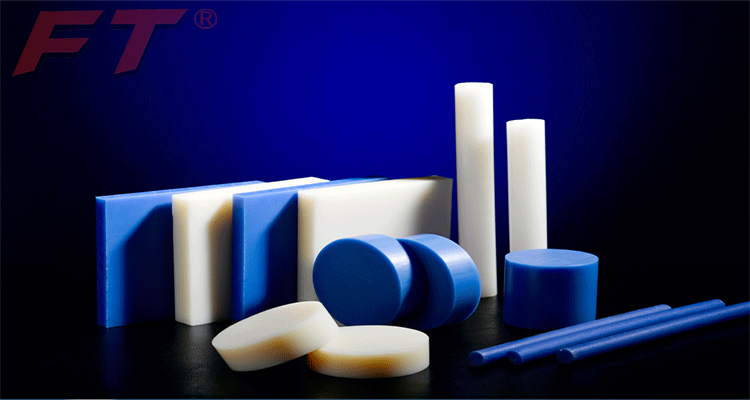

★ Engineering plastics

★ Flame retardant and smoke suppressant in plastic compounds for thermoplastic olefins,

★ Plastic building materials,

★ Select wire and cable applications,

★ Plastic fillers and coatings,

★ Fire-retardant and flame-retardant aluminum-plastic plate.

Attributes and benefits of Magnesium Hydroxide for engineering plastics:

★ Excellent flame retardancy and smoke suppression properties

★ Non-halogenated

★ Cost effective replacement for Alumina Trihydrate (ATH), Lower hardness than ATH resulting in longer equipment life

★ Thermally stable to 340°C, suitable for engineering plastic

★ Low toxicity [LD50 (oral/rat) > 5,000 Mg/Kg]

★ Non-corrosive as compared to halogen or phosphorous-containing compounds

General parameters of Magnesium Hydroxide for engineering plastics:

Mesh: | 325-2000mesh |

Whiteness: | 92%-98% |

MgO: | 62% min, available according to customer demand. |

For more info about the products, please feel free to contact our technician representatives.

We can also supply according to customized quality demand.

About our company:

Dalian Futai Mineral New Materials Technology Founded in 2009, the company is a comprehensive enterprise integrating mining and processing of mineral products, R & D and production of masterbatch, product sales and service. Since its establishment, the company has been committed to the processing of talcum powder and related filler masterbatch, and has won unanimous praise in the industry. It is a professional technical production enterprise and has won a number of awards from relevant associations in the industry.