Talc In Automotive Application

- FuTai

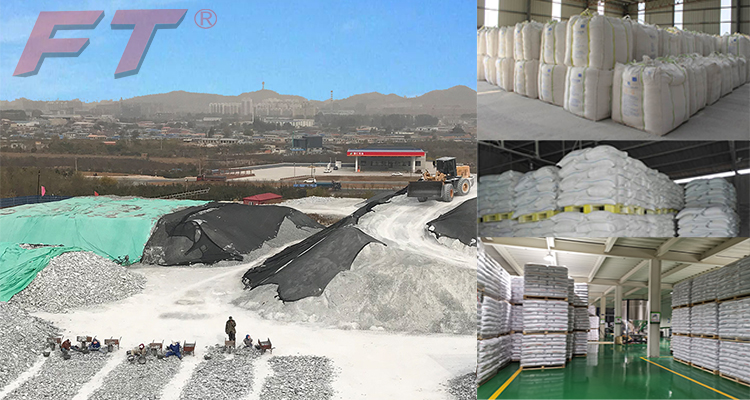

- LiaoNing, China

- Prompt delivery

- 3000T per month

Highlights

1. Talc In Automotive Application enhances the performance of polyolefin compounds, creating a variety of application possibilities.

2. Different grade talcs are available for different parts in automotive Application with a precisely controlled particle size distribution, our talc for automotive plastics ensures exact reproducibility in formulations.

3. The content of talc applied to modified plastic can significantly increase the flexural modulus, that is, the rigidity of the product.

4. Talcs can be used to replace or extend glass fiber in automotive polyamides, improving cost/performance ratio as well as isotropic dimensional stability and surface appearance.

5. Our engineering plastic grade talc powder can make plastic’s strength, shock resistance, heat resistance, hardness and ageing resistance more homogeneous.

Introduction of talc in automotive application:

Nowadays, the vehicle manufacturers are using a lot of plastics replacing metal and other materials to produce the automotive parts, considering lightweight cost control and processing. However, one of the most critical challenges to auto manufacturers is how to reduce the environmental impact of the vehicles they produce. Talc powders make excellent, green multi-functional reinforcement fillers and nucleants for automotive plastics such as polypropylene (PP) and engineering thermoplastics, allowing manufacturers to reduce part weight. The talc powder for car automotive plastics is also cost-effective replacements for glass fiber and improves scratch and mar resistance.

As an additive, modifier or filler, talc powder is widely applied to automotive industry for many parts such as:

★ under-the-hood parts

★ dashboard and interior trim

★ bumper, body panels and exterior trim

What’s more, the talc powders for engineering plastics are also applied to other industries like aircraft, electrical, household appliances.

Product features:

Futai Talc In Automotive Application improve the stiffness/impact balance, HDT and dimensional stability of lightweight thermoplastic automotive parts. By using high grade talc material and precisely controlling particle size, we mainly produce highly micronized size talc powder, with features of the high dispersity, stable color Gardner and easy color matching. The high content of silicon dioxide can improve the tensile strength and impact Strength of the products. The high fineness can improve the dimensional stability of products. It can promote advantages of engineering plastics during plastic modification.

Talc In Automotive Application offers greater strength and/or weight-savings, greater dimensional stability and flame retardation, extraordinary softness reduces machine-wear during processing, exceptionally high degree of whiteness for maximum brightness.

Main uses of Talc In Automotive Application:

★ Talcs make ideal reinforcement fillers in automotive polypropylene (PP) where they maximize stiffness and heat distortion temperature. They minimize shrinkage and thermal expansion in plastic compounds making them ideal for zero gap designs. They can be used at loadings of up to 40%.

★ Our talc can be used as nucleating agent in PA for under the hood applications and in PP for automotive dashboard and interior trim applications.

★ Our talc powder has outstanding cell nucleating performance in lightweight foamed automotive applications.

★ Our talcs for improved mechanical properties, dimensional stability and heat resistance in recycled automotive plastics.

General parameters of Talc In Automotive Application:

Mesh | 1250-5000mesh |

Whiteness | above 90%-95% |

SiO2 | 55-62% |

We recommend our regular models FT2092, FT3092, FTJ1250, 9715, 9725 to the customers who use talc powder for plastic modification for plastic processing. For more info about the products, please feel free to contact our technician representatives.

We can also supply according to customized quality demand.

Some precautions for using talcum powder:

To achieve the best results, use good talc powder, pay attention to the following points:

1. Talc powder must be subjected to surface activation treatment. The surface activation treatment of talc powder is mainly to improve the compatibility between talc powder and plastic raw materials and increase the modification effect. Different surface treatment agents should be selected for different plastics, such as Maleic anhydride grafted polypropylene is a good way.

2. The dispersibility of talc in plastic raw materials. Under the same formula, the dispersibility of talc in plastic raw materials has a great influence on the final physical and chemical properties of the modified material. It should be strictly controlled in the production process to affect the dispersibility of talc in plastics. The main factors of dispersibility in raw materials are formula, temperature, output, technological process, etc. In addition, when the amount of talc added is large, a step-by-step method can be adopted to achieve a good dispersion effect.

3. For different plastics, different specifications of talc should be selected to achieve the desired effect. This is very particular, and a bad choice may backfire. Because different plastics, different products, and different conditions of use have different requirements on raw materials, different choices must be made to achieve the desired effect.

About our company:

Dalian Futai Mineral New Materials Technology Founded in 2009, the company is a comprehensive enterprise integrating mining and processing of mineral products, R & D and production of masterbatch, product sales and service. Since its establishment, the company has been committed to the processing of talcum powder and related filler masterbatch, and has won unanimous praise in the industry. It is a professional technical production enterprise and has won a number of awards from relevant associations in the industry.