Talc Powder For Pipe

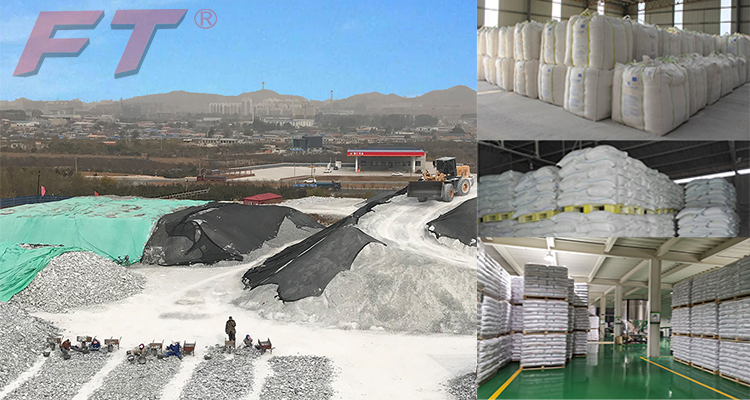

- FuTai

- LiaoNing, China

- Prompt delivery

- 3000T per month

Highlights:

1. Talc Powder for Pipe has feature of good dispersion.

2. Pipe grade talc can improve the ring stiffness of the final product.

3. Talc powder for pip can improve the ring flexibility of the final product.

4. Adding talc applied to pipe industry is cost-effective solution for the manufacturer without sacrificing end products quality.

Introduction of talc powder for pipe:

Futai talc powder for pipe is produced strictly according to this industry’s physical and chemical properties, with good dispersion and color gardener. By using this special grade talc powder for pipe, for example corrugated pipe, the manufacturer can benefit:

★ Improve end products in their ring stiffness and ring flexibility.

★ Reduce the material costs without sacrificing end products’ quality.

★ Talc powder for pip can improve the ring flexibility of the final product.

★ Adding talc applied to pipe industry is cost-effective solution for the manufacturer without sacrificing end products quality.

★ Talc powder for pipe brings for the end products good surface finish, dimensional stability.

China is the world's largest producer, consumer and exporter of talc. With the continuous improvement of people's performance requirements for plastic products, the demand for talc powder in the plastic industry is increasing.

Main uses of Talc Powder For Pipe:

PVC pipe

Corrugated pipe

PP pipe

PE pipe

General parameters of talc powder For Pipe:

Mesh | 800-2000mesh |

Whiteness | above 70%-95% |

SiO2 | 50-60% |

Due to the pipe industry involves different application. We have regular models FPI-100, FPI-200, FPI-300 for the pipe industry. For corrugated pipe, we recommend model FPI-100. For more info about the products, please feel free to contact our technician representatives.

We can also supply according to customized quality demand.

Some precautions for using talcum powder:

To achieve the best results, use good talc powder, pay attention to the following points:

1. Talc powder must be subjected to surface activation treatment. The surface activation treatment of talc powder is mainly to improve the compatibility between talc powder and plastic raw materials and increase the modification effect. Different surface treatment agents should be selected for different plastics, such as Maleic anhydride grafted polypropylene is a good way.

2. The dispersibility of talc in plastic raw materials. Under the same formula, the dispersibility of talc in plastic raw materials has a great influence on the final physical and chemical properties of the modified material. It should be strictly controlled in the production process to affect the dispersibility of talc in plastics. The main factors of dispersibility in raw materials are formula, temperature, output, technological process, etc. In addition, when the amount of talc added is large, a step-by-step method can be adopted to achieve a good dispersion effect.

3. For different plastics, different specifications of talc should be selected to achieve the desired effect. This is very particular, and a bad choice may backfire. Because different plastics, different products, and different conditions of use have different requirements on raw materials, different choices must be made to achieve the desired effect.

About our company:

Dalian Futai Mineral New Materials Technology Founded in 2009, the company is a comprehensive enterprise integrating mining and processing of mineral products, R & D and production of masterbatch, product sales and service. Since its establishment, the company has been committed to the processing of talcum powder and related filler masterbatch, and has won unanimous praise in the industry. It is a professional technical production enterprise and has won a number of awards from relevant associations in the industry.